2020 China New Design Terminal Box Ftth - GL micro module cable for aerial – GL Technology Detail:

Scope

This listed specification covers the design requirements and performance standard for the supply of optical fiber cable in the industry. It also includes GL premium designed cable with optical, mechanical and geometrical characteristics.

|

Cable type |

Application |

|

OFC-12/24/36/48/72/96/144/288 G.657A2-FASA-S1 |

Aerial installation cable |

|

OFC-12/24/36//48/72/96/144/288 G.652D-FASA-S1 |

Aerial installation cable |

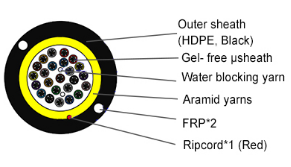

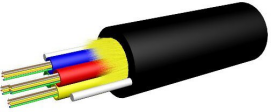

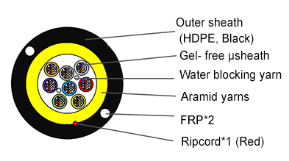

1.1 Cable Description

GL cable possesses high tensile strength and flexibility in compact cable sizes. At the same time, it provides excellent optical transmission and physical performance.

1.2 Quality

Excellent quality control is achieved through intense in-house quality check and stringent audit acceptance by ISO 9001.

1.3 Reliability

Initial and periodic product qualification tests for performance and durability are performed rigorously to ensure product reliability.

1.4 Reference

The cable which GL offered are designed, manufactured and tested according to international standards

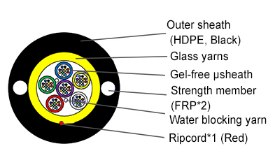

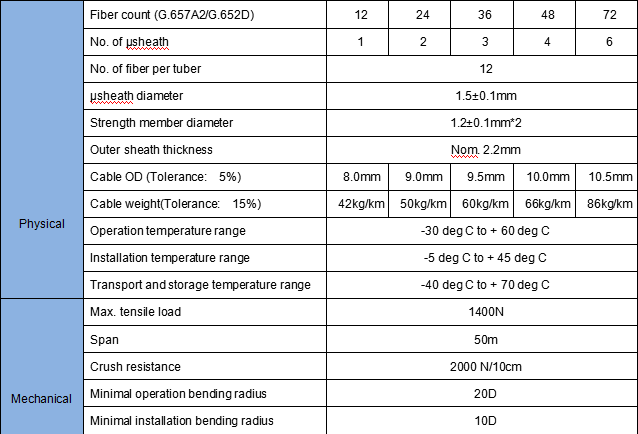

2.1 CABLE TYPE: OFC-12/24/36/48/72 G.657A2/G.652D-FASA-S1 (Module 12)

Technical Characteristics

l With excellent mechanical and environmental properties

l Has good bending performance, easy to install

Dimension and Properties

Color code scheme:

| Fiber color | red | blue | green | yellow | violet | white | orange | gray | brow n | black | aqua | rose |

| Module color | red | blue | green | yellow | violet | white | / | / | / | / | / | / |

Note: sheath thickness not consider ripcord portion

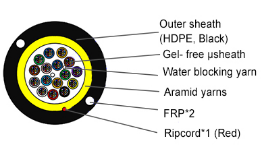

2.2 Cable Type: OFC-96 G.657A2/G.652D-FASA-S1 (Module 12)

Technical Characteristics

The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties

Multiple water blocking material filling provides dual water blocking function

Dimension and Properties

| Physical |

Fiber count (G.657A2/G.652D) |

96 |

| No. of fiber per tuber |

12 |

|

| No. of μsheath |

8 |

|

| μsheath diameter |

1.5±0.1mm |

|

| Strength member diameter |

1.2±0.1mm*2 |

|

| Outer sheath thickness |

Nominal 2.2mm |

|

| Cable OD |

11.3mm±5% |

|

| Cable weight |

72kg/km±15% |

|

| Operation temperature range |

-30 deg C to + 60 deg C |

|

| Installation temperature range |

-5 deg C to + 40 deg C |

|

| Transport and storage temperature range |

-40 deg C to + 70 deg C |

|

|

Mechanical |

Max. tensile load |

1600N |

| Span |

50m |

|

| Crush resistance |

2000 N/10cm |

|

| Minimal installation bending radius |

20 x OD |

|

| Minimal operation bending radius |

10 x OD |

Color code scheme:

| Fiber color | red | blue | green | yellow | violet | whit e | orange | grey | brow n | blac k | aqua | rose |

| Tube color | red | blue | green | yellow | violet | whit | orange | grey | / | / | / | / |

2.3 Cable Type: OFC-144 G.657A2/G.652D-FASA-S1 (Module 12)

Technical Characteristics

l The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

l The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties

l Multiple water blocking material filling provides dual water blocking function

Dimension and Properties

| Physical |

Fiber count (G.657A2/G.652D) |

144 |

| No. of fiber per tuber |

12 |

|

| No. of μsheath |

12 |

|

| μsheath diameter |

1.5±0.1mm |

|

| Strength member diameter |

1.4±0.1mm*2 |

|

| Outer sheath thickness |

Nominal 2.4mm |

|

| Cable OD |

12.8mm±5% |

|

| Cable weight |

82kg/km±15% |

|

| Operation temperature range |

-30 deg C to + 60 deg C |

|

| Installation temperature range |

-5 deg C to + 40 deg C |

|

| Transport and storage temperature range |

-40 deg C to + 70 deg C |

|

| Mechanical |

Max. tensile load |

1800N |

| Span |

50m |

|

| Crush resistance |

2000 N/10cm |

|

| Minimal installation bending radius |

20 x OD |

|

| Minimal operation bending radius |

10 x OD |

Color code scheme:

| Fiber color | red | blue | green | yellow | violet | white | orange | grey | brown | black | aqua | rose |

| Modules color | red | blue | green | yellow | violet | white | orange | grey | brown | light green | aqua | rose |

2.4 Cable Type: OFC-288 G.657A2/G.652D-FASA-S1 (Module 12)

Technical Characteristics

l The unique extruding technology provides the fibers in the tube with good flexibility and bending endurance

l The unique fiber excess length control method provides the cable with excellent mechanical and environmental properties

l Multiple water blocking material filling provides dual water blocking function

Dimension and Properties

| Physical |

Fiber count (G.657A2/G.652D) |

288 |

| No. of fiber per tuber |

12 |

|

| No. of μsheath |

24 |

|

| μsheath diameter |

1.5±0.1mm |

|

| Strength member diameter |

1.6±0.1mm*2 |

|

| Outer sheath thickness |

Nominal 2.6mm |

|

| Cable OD |

15.7mm±5% |

|

| Cable weight |

128kg/km±15% |

|

| Operation temperature range |

-30 deg C to + 60 deg C |

|

| Installation temperature range |

-5 deg C to + 40 deg C |

|

| Transport and storage temperature range |

-40 deg C to + 70 deg C |

|

|

Mechanical |

Max. tensile load |

2000N |

| Span |

50m |

|

| Crush resistance |

2000 N/10cm |

|

| Minimal installation bending radius |

20 x OD |

|

| Minimal operation bending radius |

10 x OD |

Color code scheme:

| Fiber color | red | blue | green | yellow | violet | white | orange | grey | brown | black | aqua | rose |

| Modules color | red | blue | green | yellow | violet | white | orange | grey | brown | light green | aqua | rose |

4. Test Requirements

The cable is in accordance with applicable standard of cable and requirement of customer. The following test items are carried out according to corresponding reference.

Routine tests of optical fiber

| Mode field diameter | IEC 60793-1-45 |

| Mode field Core/clad concentricity | IEC 60793-1-20 |

| Cladding diameter | IEC 60793-1-20 |

| Cladding non-circularity | IEC 60793-1-20 |

| Attenuation coefficient | IEC 60793-1-40 |

| Chromatic dispersion | IEC 60793-1-42 |

| Cable cut-off wavelength | IEC 60793-1-44 |

Test lists

4.1 Tension Loading Test

| Test Standard | IEC 60794-1-2 E1 |

| Sample length | No less than 50 meters |

| Load | Max. tension load |

| Duration time | 1 minute |

| Test results | Attenuation is reversible |

| No damage to outer jacket and inner elements |

4.2 Crush/Compression Test

| Test Standard | IEC 60794-1-2 E3 |

| Load | Crush load |

| Duration time | 1minute |

| Test number | 3 |

| Test results | After test, additional attenuation:≤0.05dB |

| No damage to outer jacket and inner elements |

4.3 Impact Resistance Test

| Test Standard | IEC 60794-1-2 E4 |

| Impact energy | 5J |

| Radius | 300mm |

| Impact points | 3 |

| Impact number | 1 |

| Test result | After test, additional attenuation:≤0.05dB |

| No damage to outer jacket and inner elements |

4.4 Repeated Bending Test

| Test Standard | IEC 60794-1-2 E6 |

| Bending radius | 20 X diameter of cable |

| Cycles | 25 cycles |

| Test result | After test, additional attenuation:≤0.05dB |

| No damage to outer jacket and inner elements |

4.5 Torsion/Twist Test

| Test Standard | IEC 60794-1-2 E7 |

| Sample length | 2m |

| Angles | ±180 degree |

| cycles | 5 |

| Test result | After test, additional attenuation:≤0.05dB |

| No damage to outer jacket and inner elements |

4.6 Temperature cycling Test

| Test Standard | IEC 60794-1-2 F1 |

| Temperature step | +20℃ →-40℃ →+70℃ |

| Time per each step | 12 hrs |

| Cycles | 2 |

| Test result | Attenuation variation for reference value (the attenuation to be measured before test at +20±3℃) ≤ 0.10 dB/km |

4.7 Water penetration Test

| Test Standard | IEC 60794-1-22 F5C |

| Height of water column | 1m |

| Sample length | 3m |

| Test time | 24 hrs |

| Test result | No water leakage from the opposite of the sample |

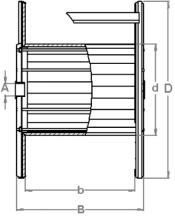

5.Packing and Drum

4.1 GL cables are packed in carton, coiled on Bakelite & wooden drum. During transportation, right tools should be used to avoid damaging the package and to handle with ease. Cables should be protected from moisture; kept away from high temperature and fire sparks; protected from over bending and crushing; protected from mechanical stress and damage.

|

GL Cable |

D*d*B cm(weights kg) D: including seal plate thickness |

|

|

Length Type |

2Km/reel |

4Km/reel |

|

OFC-12 G.657A2/G.652D-FASA-S1 (Module 12) |

Wooden 115*60*62(283) |

|

|

OFC-24 G.657A2/G.652D-FASA-S1 (Module 12) |

/ |

Wooden 125*60*62(325) |

|

OFC-36 G.657A2/G.652D-FASA-S1 (Module 12) |

Wooden 125*60*72(365) |

|

|

OFC-48 G.657A2/G.652D-FASA-S1 (Module 12) |

/ |

Wooden 125*60*72(389) |

|

OFC-72 G.657A2/G.652D-FASA-S1 (Module 12) |

/ |

Wooden 130*60*72(474) |

|

OFC-96 G.657A2/G.652D-FASA-S1 (Module 12) |

/ |

Wooden 135*65*77(423) |

|

OFC-144 G.657A2/G.652D-FASA-S1 (Module 12) |

Wooden 125*70*72(289) |

/ |

|

OFC-288 G.657A2/G.652D-FASA-S1 (Module 12) |

Wooden 135*75*87(391) |

/ |

Note: The drum size & cable weight as above is estimated and final size & weight shall be confirmed before shipment.

4.1 The color of cable marking is white. (The printing shall be carried out at interval of 1 meter on the outer sheath of cable) The inner end of cable is then sealed with end cap to prevent ingress of water and is made available for testing. The outer end of cable is equipped with end cap. Outer sheath marking legend can be changed according to user’s requests.

4.2 Outdoor cable packing Bakelite & wooden drum

Strong wooden batten protection

Product detail pictures:

Related Product Guide:

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for 2020 China New Design Terminal Box Ftth - GL micro module cable for aerial – GL Technology, The product will supply to all over the world, such as: Burundi , Moldova , Cambodia , Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.