Structure Design:

Main Features:

• It can be installed without power off.

• Easy to install with light weight and small diameter

• Large span length (up to 1000 meters) suitable for different requirements

• Good mechanical and environmental performance

• Flat FRP armored for better anti-rodent function

Cable Technical Parameter:

Double Jacket (Span 150m for reference):

| Fibers |

OD of Cable

(mm) |

Cable weight

(kg/km) |

Min bending radius(mm) |

Tensile (N) |

Crush (N/100mm) |

Temperature (ºC) |

| Static |

Dynamic |

Short-term |

Long-term |

Short-term |

Long-term |

| 12 |

13.5 |

165 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

Storage/Operation:

-40ºC~+70ºC |

| 24 |

13.5 |

165 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

| 36 |

13.5 |

165 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

| 48 |

14.8 |

187 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

| 72 |

14.8 |

187 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

| 96 |

15.4 |

208 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

| 144 |

18.2 |

278 |

10D |

20D |

5000 |

2500 |

3000 |

1000 |

| Note: "D" means cable diameter |

Tripe Jacket (Span 300m for reference):

| Item |

Value |

| Span |

300 M |

| Fiber Count |

12 |

24 |

48 |

144 |

| PBT Tube |

1 |

2 |

4 |

12 |

| Fiber Count/ Tube |

12 |

12 |

12 |

12 |

| Filler |

6 |

5 |

3 |

0 |

| OD of Tube/mm |

2.0±0.1 |

2.0±0.1 |

2.0±0.1 |

1.9±0.1 |

| Thickness of Tube/mm |

0.30±0.05 |

0.30±0.05 |

0.30±0.05 |

0.30±0.05 |

| Central Strength FRP |

2.8 |

2.8 |

2.8 |

2.8 |

| Coated FRP |

- |

- |

- |

5.6 |

| Water Blocking Material |

Water Blocking Yarn+Water Blocking Tape |

| Rip cord |

Polyester yarn*2 |

| Water Blocking Material |

Water Blocking Yarn+Water Blocking Tape |

| Inner Sheath |

Nominal Thickness 1.0mm HDPE |

| Peripheral Strength Member |

Aramid Yarn |

| Rip cord |

Polyester yarn*2 |

| Middle Sheath |

Nominal Thickness 1.0mm HDPE |

| Armor |

Flat FRP 3.0*1.0mm |

Flat FRP

3.0*1.0mm |

| Water Blocking Material |

Water Blocking Yarn+Water Blocking Tape |

| Rip cord |

Polyester yarn*2-Red |

| Outer Sheath |

Nominal Thickness 2.0mm HDPE |

Nominal Thickness 2.0mm HDPE |

Nominal Thickness 2.0mm HDPE |

Nominal Thickness 2.0mm HDPE |

| OD of Cable/mm |

17.8±0.3 |

17.8±0.3 |

17.8±0.3 |

20.5±0.3 |

| Weight |

294kg/km |

294kg/km |

297kg/km |

392kg/km |

Note:

1.Flooding jelly compound default

2.The relevant technical parameters can be adjusted according to the customers’ demands;

3.The block water way can be adjusted according to the customers’ demands;

4.The design flame resistance,anti-rodent,termite resistant cable according to the customers'demands.

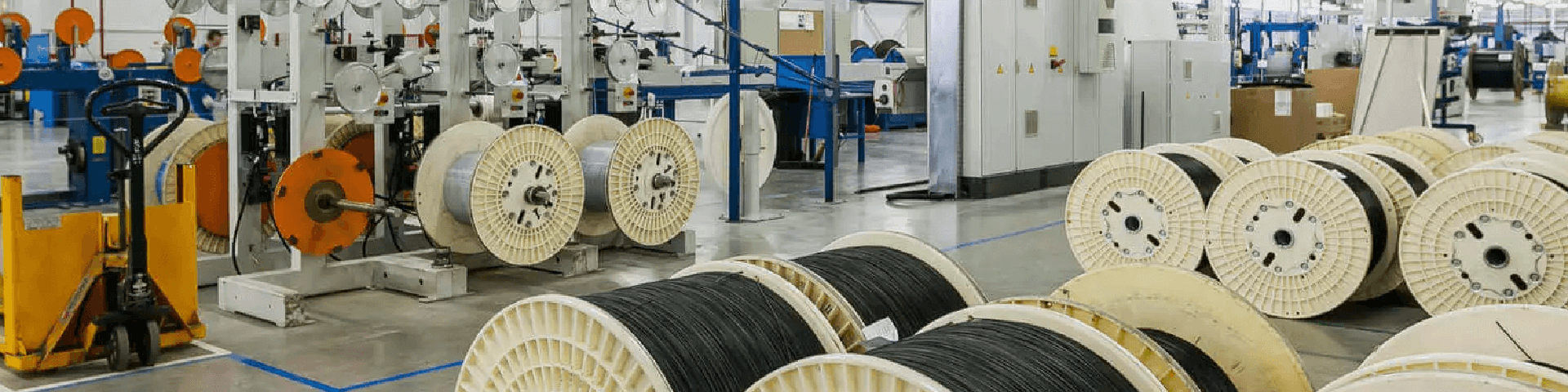

How to Ensure the Quality and Performance of Your Fiber Optic Cable?

We control the products quality from the raw material to the finish produts All the raw material should be tested to match the Rohs standard when they arrived at our manufacture.We control the quality during the producing process by advanced technology and equipments. We test the finished products according to the test standard. Approved by various professional optical and communication product institution , GL also conduct various in-house testing in its own Laboratory and Test Center. We also conduct test with special arrangement with the Chinese Government Ministry of Quality Supervision & Inspection Center of Optical Communication Products(QSICO).

Quality Control - Test Equipment and Standard:

Feedback: In order to meet the world’s highest quality standards, we continuously monitor feedback from our customers. For comments and suggestions, please, contact us, Email: [email protected].

Feedback: In order to meet the world’s highest quality standards, we continuously monitor feedback from our customers. For comments and suggestions, please, contact us, Email: [email protected].