China OEM Air Blown Fiber Microduct - Submarine Optical Fiber Cable – GL Technology Detail:

Application :

Submarine water and vertical shaft

Submarine Optical cables are cables wrapped in insulating materials, mainly laid on the seabed, used for telecommunications and network transmission between countries;Submarine optical cable system is mainly used to connect the cable and Internet, it is divided into shore equipment and underwater equipment two major, submarine optical cable is the most important underwater equipment is the most vulnerable part.

Characteristic:

1,Excellent mechanical and temperature performance;

2,Better tensile strength performance with steel Wires.

Features:

1,High strength fiber — ensure stable signal transmission and effective peration life.

2,Special water blocking jelly — prevent the ingress of water or hydrogen gas.

3,On-line fiber excess control — exact fiber excess in finished cable.

4,Customized Cables with different length and specification.

5,Stainless steel tube — avoid external damages to optic fiber.

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for China OEM Air Blown Fiber Microduct - Submarine Optical Fiber Cable – GL Technology, The product will supply to all over the world, such as: Bahrain , Mexico , Iran , Our company always provides good quality and reasonable price for our customers. In our efforts, we already have many shops in Guangzhou and our products have won praise from customers worldwide. Our mission has always been simple: To delight our customers with best quality hair products and deliver on time. Welcome new and old customers to contact us for the future long term business relationships.

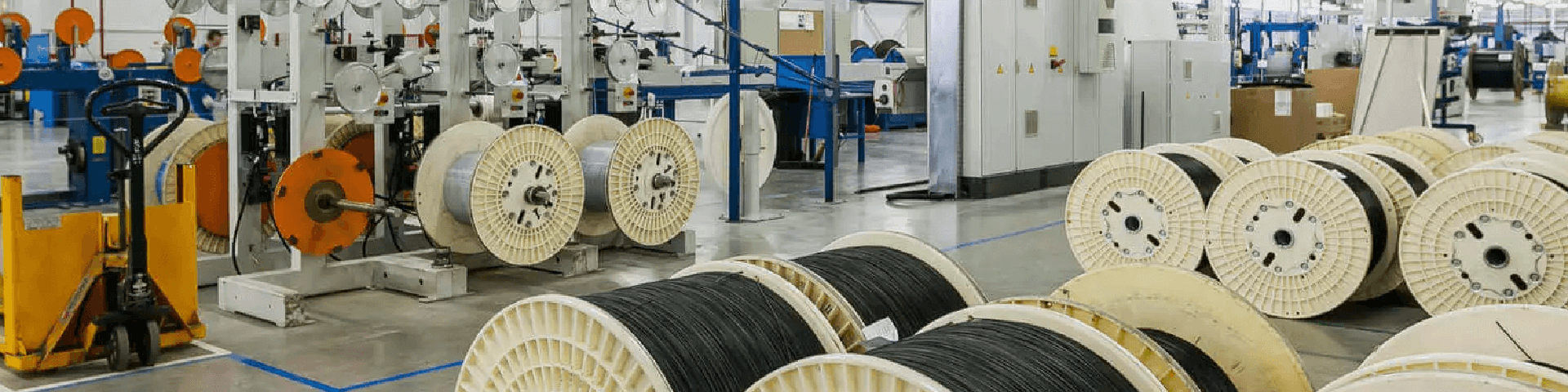

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.