Chinese Professional 16 Core Termination Box - OPGW Typical Designs of Stranded Stainless Steel Tube – GL Technology Detail:

Application: Aerial , Overhead , Outdoor

Characteristic:

1,High quality IEC607948 IEEE1138 standards for designing, testing and producing with grade A materials available to ensure long-term reliability .

2,Engineering support supervising and providing its own line of accessories hardware .

3,Larger tensile strength and fault current capacity to reach a better balance of electrical and mechanical performance.

Advantages of GL OPGW fiber optic cable:

1,Three typical designs: central tube,stranded wire,PBT loose tube;

2,200km OPGW cable regular production time about 20 days;

3,Type test including salt corrosion,suitable in harsh corrosive environment,especially near the sea.

OPGW has two fiber type : one is single mode G652D , and the other is G655 , sometimes they mixed together , such like OPGW-36B1+12B4-93 [78.8;53.9] . Fiber optic cable OPGW, usually 12~48 fibers,GL can max produced 96 fibers OPGW fiber optic cable, jelly filled and fiber contained central PBT loose/aluminum cladding steel/aluminum tube, outer with AA/ACS wires armored, detailed specification on your request.

| ITU-TG.652 | Characteristics of a single mode optical fiber. |

| ITU-TG.655 | Characteristics of a non-zero dispersion -shifted single mode fibers optical. |

| EIA/TIA598 B | Col code of fiber optic cables. |

| IEC 60794-4-10 | Aerial optical cables along electrical power lines-family specification for OPGW. |

| IEC 60794-1-2 | Optical fiber cables -part test procedures. |

| IEEE1138-2009 | IEEE Standard for testing and performance for optical ground wire for use on electric utility power lines. |

| IEC 61232 | Aluminum -Clad steel wire for electrical purposes. |

| IEC60104 | Aluminum magnesium silicon alloy wire for overhead line conductors. |

| IEC 6108 | Round wire concentric lay overhead electrical stranded conductors. |

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Chinese Professional 16 Core Termination Box - OPGW Typical Designs of Stranded Stainless Steel Tube – GL Technology, The product will supply to all over the world, such as: Mexico , Comoros , Munich , Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

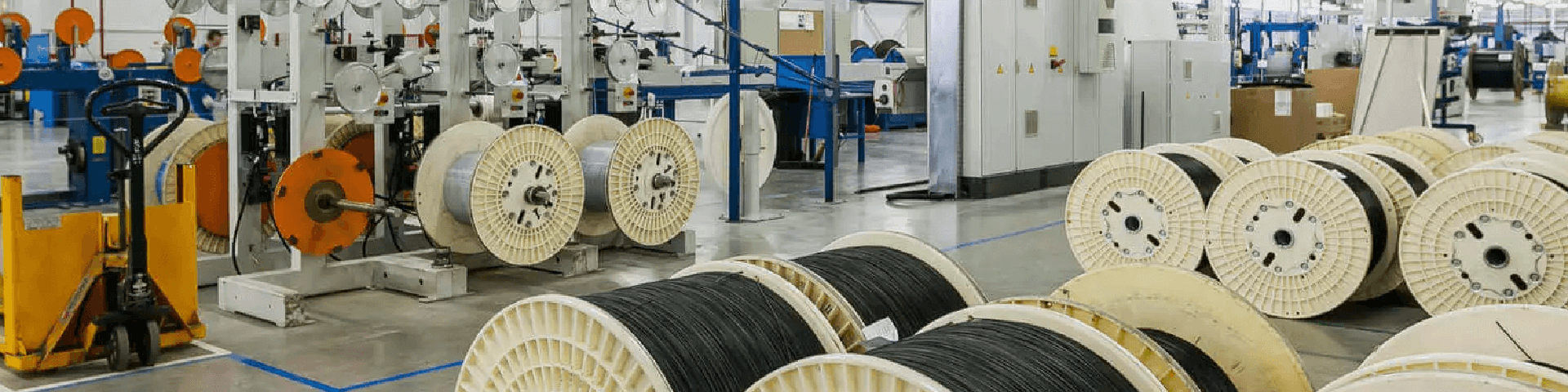

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.