Factory wholesale Lc Connector - Stranded Loose Tube Anti Rodent Fiber Optic Cable GYTA33(缺少产品图片) – GL Technology Detail:

Fiber Optic Cable GYTA33, 2~72 fibers, central strength member (steel), jelly filled, fiber contained loose tube and pp filler (if necessary) stranded, water blocking jelly, copolymer coated aluminum tape, PE inner sheath, armored by a layer of steel wires, PE outer sheath. G652d SM fiber, detailed specification on your request.

Application:

1,Laying modes: direct buried & under-water.

2,Applications: Long-distance communication, local trunk line, catv & computer networks system.

Technical Parameter:

| Fiber count | 2~30 | 32~36 | 38~60 | 62~72 | 2~36 | 38~72 | |

| CSM/Steel wire (mm) | --/1.5 | --/2.0 | --/1.8 | 2.4/1.8 | --/2.0 | 2.4/1.8 | |

| Element number | 5 | 6 | 5 | 6 | 6 | 6 | |

| Max. cores in tube | 6 | 6 | 12 | 12 | 6 | 12 | |

| Diameter of inner sheath | 8.3 | 8.8 | 9.1 | 9.7 | 10.5 | 10.5 | |

| Steel wire diameter and No. | Φ1.0/28 | Φ1.0/29 | Φ1.0/30 | Φ1.0/32 | Φ1.5/24 | Φ1.5/24 | |

| Cable diameter approx (mm) | 14.3 | 14.8 | 15.1 | 15.7 | 17.5 | 17.5 | |

| Weight approx (kg/km) | 315 | 328 | .340 | 360 | 520 | 520 | |

| Tensile strength (N) | Long term | 4000 | 10000 | ||||

| Short term | 10000 | 2000 | |||||

| Crush Resistance(N/100mm) | Long term | 3000 | |||||

| Short term | 5000 | ||||||

| Bending Radius (mm) | Dynamic | ≥30 ×Dia. Of cable | |||||

| Static | ≥15×Dia. Of cable | ||||||

| Operating Temperature (°C) | -40°C ~+ 70°C | ||||||

| Application | Directly burial and Under water | ||||||

Notes:

Only a part of Joint Box/Splice Closure/Joint Closure are listed here. We can depend on customer’s requirement to producing the different model Joint Box/Splice Closure/Joint Closure.

We supply OEM&ODM Service. Contact Us Now !

E-Mail: [email protected]

WhatsApp:+86 18073118925 Skype: opticfiber.tim

Product detail pictures:

Related Product Guide:

We're commitment to offer you the competitive price ,remarkable products excellent, also as fast delivery for Factory wholesale Lc Connector - Stranded Loose Tube Anti Rodent Fiber Optic Cable GYTA33(缺少产品图片) – GL Technology, The product will supply to all over the world, such as: Luxembourg , Ottawa , Spain , Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

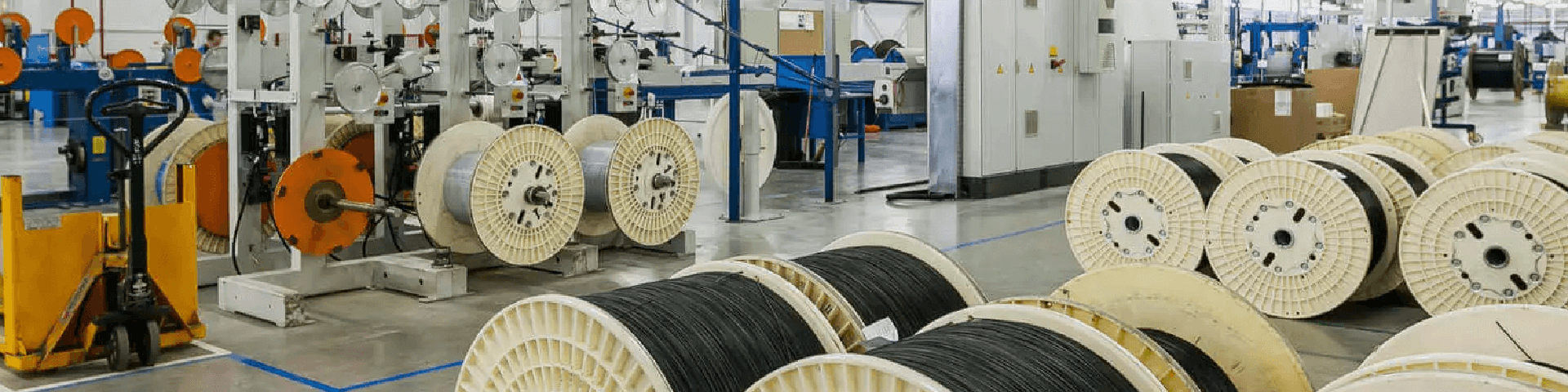

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.