Fast delivery Military Cable - HYV Indoor Telephone Cable BC/PE /PVC 100 Pairs 0.4mm – GL Technology Detail:

MECHANICAL AND THERMAL PROPERTIES

Temperature range during operation (fixed state):-20°C ~ +70°C

Temperature range during installation (mobile state):-20°C ~ +50°C

Minimum bending radius:15x Overall Diameter

Cable Construction

1, Conductor:99.9% pure annealed copper; Diameter of wire: 0.40 mm; Tolerance:± 0.01 mm

2, Insulation:Polyethylene; Diameter of Insulation: 0.69 mm; Tolerance:± 0.02 mm; Nominal thickness: 0.145 mm

3, Twisting pair:2 x Insulated wire

|

Number of Pairs |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

Insulation Color Coding |

a |

white |

white |

white |

white |

white |

red |

red |

red |

red |

red |

|

b |

blue |

orange |

green |

brown |

gray |

blue |

orange |

green |

brown |

gray |

|

|

Number of Pairs |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

|

Insulation Color Coding |

a |

Black |

Black |

Black |

Black |

Black |

Yellow |

Yellow |

Yellow |

Yellow |

Yellow |

|

b |

blue |

orange |

green |

brown |

gray |

blue |

orange |

green |

brown |

gray |

|

4 , Cable Make-up:4X25 Pairs shall be form a sup-unit.

|

NO.of Pairs in Cable |

Make-up |

NO.of Pairs in Spare Per Unit |

NO.of Unusable Pairs Allowed |

||

|

NO. of Unite in Centre and Successive Layers |

|||||

|

centre |

1st Layer |

2st Layer |

|||

|

100/0.4 |

4×25 |

—- |

—- |

1 |

1 |

5 , Color of tape Lappings within unit or a double or quadruple unit for cables.

|

Unit |

Colour of Tape Lappings for Supper Unit |

|||

|

NO.of Unit |

Colour of Tape Lappings |

NO.of Supper Unit |

NO.of Pairs |

|

|

100 Pairs |

50 Pairs |

|||

|

1 |

White-blue |

White |

White |

1~25 |

|

2 |

White-orange |

26~50 |

||

|

3 |

White-green |

White |

51~75 |

|

|

4 |

White-brown |

76~100 |

||

6, Color of Pairs in spare.

|

NO. of Spare Wire |

Insulation Color Coding |

|

|

a |

b |

|

|

1 |

White |

red |

7, Core Wrapping:The cable core shall be wrapped with a continuous protective layer of one or two tapes ,lapped Helically or laid longitudinally.

8, Rip Cord:Nylon Yarn

9, Outer Sheath:PVC (GRAY RAL 7035)

|

Cable Size |

Nominal Thickness(mm) |

Min. Thickness at any Point(mm) |

Outer Diameter (Approx.)CXH (mm) |

|

100/0.4 |

1.60 |

1.4 |

16.6 |

10, Sheath Marking:According to the customer request

11, Packing and Weight:

|

Cable Size |

Drum Material |

Drum Length |

Wooden Drum Size |

Net. Weigh t Kg/drum(Approx.) |

Gross.Weight Kg/drum(Approx.) |

|

100/0.4 |

Wood drum |

1.00 |

1200×500×620 |

395 |

495 |

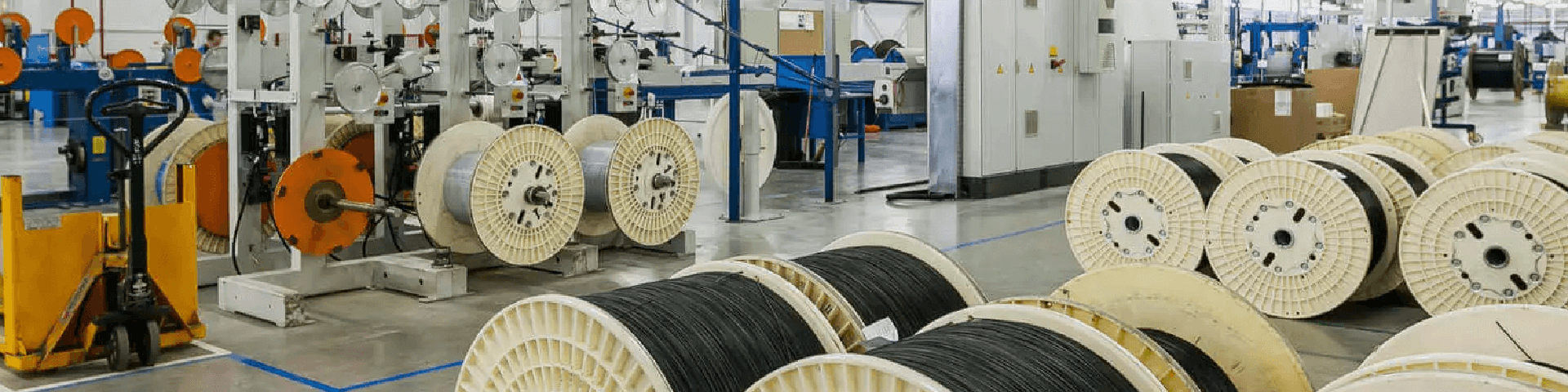

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Fast delivery Military Cable - HYV Indoor Telephone Cable BC/PE /PVC 100 Pairs 0.4mm – GL Technology, The product will supply to all over the world, such as: Swiss , Montpellier , Mauritius , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.