Structure Design:

Main Features:

●Excellent mechanical and temperature performance guaranteed by the accurate excess fiber length

●Critical protection to fibers,

●Excellent crush resistance and flexibility

●The following measures are taken to ensure the water blocking performance of the cable:

- Single steel wire used as the central strength member

- Special water-blocking filling compound in the loose tube.

PSP moisture barrier

- water-blocking yarn and water swellable material tape double water proof

Cable Technical Parameter:

|

Fiber Core

|

8

|

12

|

16

|

24

|

32

|

48

|

60

|

72

|

96

|

144

|

|

No of loose tube.

|

1

|

2

|

2

|

4

|

4

|

4

|

6

|

6

|

8

|

12/0

|

|

No of filler

|

4

|

3

|

3

|

1

|

1

|

1

|

0

|

0

|

0

|

0

|

|

Fiber No. per tube

|

8

|

6

|

8

|

6

|

8

|

12

|

10

|

12

|

12

|

12

|

|

Loose tube material

|

PBT

|

|

Central strength member Steel wire

|

Steel wire

|

|

Outer sheath

|

PE

|

|

Cable OD mm

|

12

|

12

|

12

|

12

|

12

|

12

|

12.5

|

12.5

|

14.5

|

14.5

|

|

Cable weight kg/km

|

155

|

155

|

155

|

155

|

155

|

155

|

190

|

210

|

235

|

255

|

|

Operation temperature range

|

-40 ℃ to + 70 ℃

|

|

Installation temperature range

|

-40 ℃ to + 70 ℃

|

|

Transport and storage temperature range

|

-40 ℃ to + 70 ℃

|

|

Allowable Tensile Load(N)

|

Short term:4000 Long term:3000

|

|

Crush resistance

|

Short term 3000 N/100mm Long term :1000N/100MM

|

|

Minimal installation bending radius

|

20 x OD

|

|

Minimal operation bending radius

|

10 x OD

|

|

Mode Field Diameter @ 1310 nm

|

8.7-9.5 mum

|

| |

|

|

|

Mode Field Diameter @ 1550 nm

|

9.8-10.8mum

|

| |

|

|

|

|

Cladding diameter

|

|

125.0 ±± 0.7mm

|

| |

|

|

|

|

Core/cladding concentricity error

|

|

0.6 um

|

|

Cladding non-circularity

|

|

1.0 %

|

|

Refractive index profile

|

|

Step

|

|

Design

|

|

Matched cladding

|

|

Primary coating material

|

|

UV curable acrylate

|

|

Primary coating Diameter

|

|

235-250um

|

|

Optical Characteristics

|

|

|

|

Attenuation

|

|

@ 1310nm

|

£ 0.36 dB/km (cabling)

|

| |

@ 1383±3nm

|

£ 0.34 dB/km

|

| |

|

@ 1550nm

|

£ 0.22dB/km (cabling)

|

|

Dispersion

|

|

@ 1288 ~ 1339nm

|

£ 3.5 ps/nm×km

|

| |

@ 1550nm

|

£ 18 ps/nm×km

|

| |

|

| |

|

|

|

|

Zero dispersion wavelength

|

|

1300 – 1324 nm

|

|

Dispersion slope at zero dispersion wavelength

|

£ 0.092 ps/nm2×km

|

|

Cabled cut-off wavelength (cc)

|

|

£ 1260 nm

|

|

Polarization mode dispersion link value

|

£ 0.2 ps/√km

|

|

Mechanical Characteristics

|

|

|

|

Proof stress level

|

|

≥0.69 GPa

|

|

The loss increase of 100 turns of fiber loosely wound with

|

£0.05dB (at 1550nm)

|

|

25mm radius

|

|

|

|

Effective group index of refraction Neff

|

1.466(at 1310nm)

|

|

Effective group index of refraction Neff

|

1.467 (at 1550nm)

|

Notes:

1.Flooding jelly compound default

2.The relevant technical parameters can be adjusted according to the customers’ demands;

3.The block water way can be adjusted according to the customers’ demands;

4.The design flame resistance,anti-rodent,termite resistant cable according to the customers'demands.

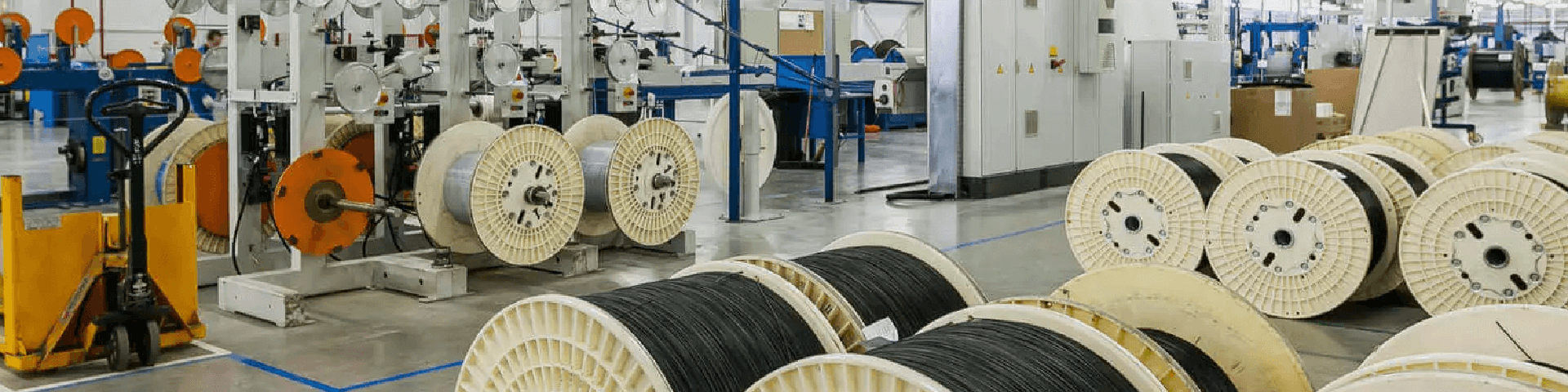

How to Ensure the Quality and Performance of Your Fiber Optic Cable?

We control the products quality from the raw material to the finish produts All the raw material should be tested to match the Rohs standard when they arrived at our manufacture.We control the quality during the producing process by advanced technology and equipments. We test the finished products according to the test standard. Approved by various professional optical and communication product institution , GL also conduct various in-house testing in its own Laboratory and Test Center. We also conduct test with special arrangement with the Chinese Government Ministry of Quality Supervision & Inspection Center of Optical Communication Products(QSICO).

Quality Control - Test Equipment and Standard:

Feedback: In order to meet the world’s highest quality standards, we continuously monitor feedback from our customers. For comments and suggestions, please, contact us, Email: [email protected].

Feedback: In order to meet the world’s highest quality standards, we continuously monitor feedback from our customers. For comments and suggestions, please, contact us, Email: [email protected].