High reputation Armored Multi Pair Telephone Cable - Nylon Anti Termite Steel Armored Fiber Cable With Nylon Jacket – GL Technology Detail:

Coated nylon jacket provide anti termite performance and with additional e glass yarn strength for anti rodent, idea for the UG Conduit and directly buried in a harsh environment .Central loose tube for 2-36core design with costly cable, single mode 9/125 and multi mode 50/125 as options.

Technical Parameter:

|

Fiber Count |

36 |

Central strength member Material |

FRP |

|

Fiber type |

62.5/125 |

Peripherals Strength member |

Corrugated steel armored |

|

Max. No of loose tube |

3 |

Nylon jacket thickness |

0.5mm Blue (anti-termite) |

|

Fiber No. per tube |

12 |

Water blocking |

Gel filling compound in loose tube & water block tape around cable |

|

Loose tube Material |

PBT |

Operation temperature range |

-40 ℃ to + 70 ℃ |

|

Filler Material |

PE |

Installation temperature range |

-40 ℃ to + 70 ℃ |

|

Number of filler |

2 |

Transport and storage temperature range |

-40 ℃ to + 70 ℃ |

|

Inner Sheath Material |

MDPE Black |

Crush resistance |

Short term :3000N/100MM Long term: 1100N/100MM |

|

Outer sheath Material |

HDPE Black |

Minimal installation bending radius |

20 x OD |

|

Cable overall diameter |

12.2±0.2 mm |

Minimal operation bending radius |

10 x OD |

|

Cable weight |

Approx 86 kg/km |

Allowable Tensile Load(N) |

3000N |

Notes:

Only a part of Joint Box/Splice Closure/Joint Closure are listed here. We can depend on customer’s requirement to producing the different model Joint Box/Splice Closure/Joint Closure.

We supply OEM&ODM Service. Contact Us Now !

E-Mail: [email protected]

WhatsApp:+86 18073118925 Skype: opticfiber.tim

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for High reputation Armored Multi Pair Telephone Cable - Nylon Anti Termite Steel Armored Fiber Cable With Nylon Jacket – GL Technology, The product will supply to all over the world, such as: Lyon , Niger , United Kingdom , Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

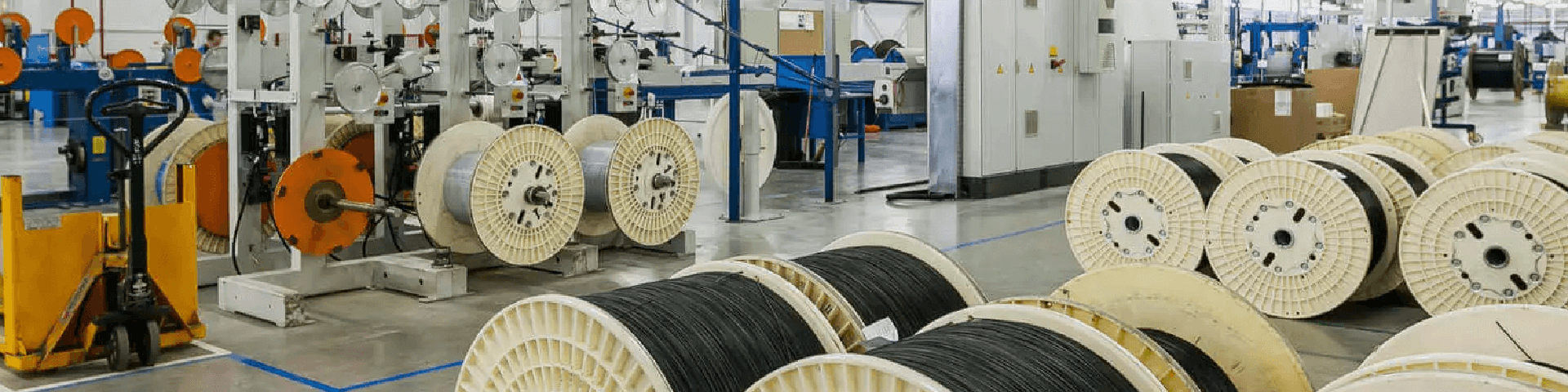

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.