Hot Selling for Ortronics Fiber Optic Patch Panel - FC Fiber Optical Adapter Adaptor – GL Technology Detail:

Characteristics

1. Low insertion loss and back reflection loss

2. High precision alignment

3. Nickel plated brass body

4. For single mode or multimode applications

5. Selection of casing material and casing material

6. ISO9001:2008, in line with ROHS

Advantages

Meets ANSL Bellcore TIA / EIA IEC standards

High precision size

Ceramic or bronze casing

Low insertion loss (<0.2dB), high return loss (≥50dB)Interchangeability exceeds thousand, repeatability is less than 0.2dB

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for Hot Selling for Ortronics Fiber Optic Patch Panel - FC Fiber Optical Adapter Adaptor – GL Technology, The product will supply to all over the world, such as: UK , Iceland , Albania , Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

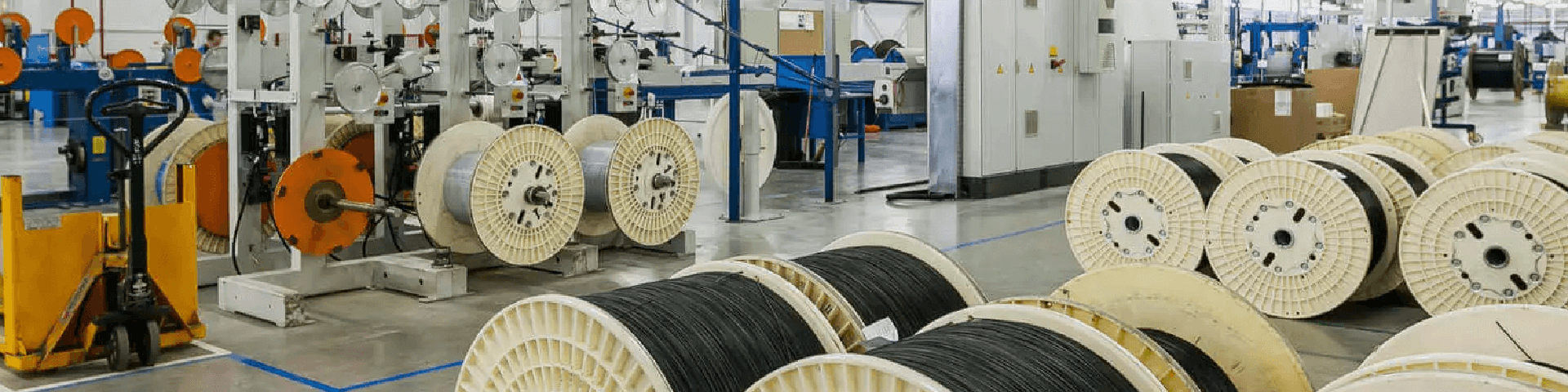

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.