New Arrival China Tactical Cable - Micromoudule 12/24 Core Duct G.657A2 / G.652D (Module 12) – GL Technology Detail:

Technical Characteristics:

1,With excellent mechanical and environmental properties2,Low weight, easy to install and joint

Dimension and Properties:

|

Physical

|

Fiber count (G.657A2/G.652D)

|

12

|

24

|

|

μsheath No.

|

1

|

2

|

|

|

Fiber No. per module

|

12

|

||

|

μsheath diameter

|

1.5±0.1mm

|

||

|

FRP diameter

|

(1.0±0.1mm)*2

|

||

|

Outer sheath thickness

|

Nominal 2.0mm

|

||

|

Cable OD

|

7.4±0.5mm

|

8.2±0.5mm

|

|

|

Cable weight

|

32kg/km±15%

|

38kg/km±15%

|

|

|

Operation temperature range

|

-30 deg C to + 60 deg C

|

||

|

Installation temperature range

|

-5 deg C to + 40 deg C

|

||

|

Transport and storage temperature range

|

-40 deg C to + 70 deg C

|

||

|

Mechanical

|

Max. tensile load

|

100daN

|

|

|

Crush resistance

|

200daN/10cm

|

||

|

Minimal installation bending radius

|

20 x OD

|

||

|

Minimal operation bending radius

|

10 x OD

|

||

Color code scheme:

| Fiber color | red | blue | green | yellow | violet | white | orange | grey | brown | black | aqua | rose |

| Modules color | red | blue | / | / | / | / | / | / | / | / | / | / |

Note: Sheath thickness not consider ripcord portion

OEM Services is available!

E-mail:[email protected]

Product detail pictures:

Related Product Guide:

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for New Arrival China Tactical Cable - Micromoudule 12/24 Core Duct G.657A2 / G.652D (Module 12) – GL Technology, The product will supply to all over the world, such as: Australia , venezuela , Los Angeles , Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

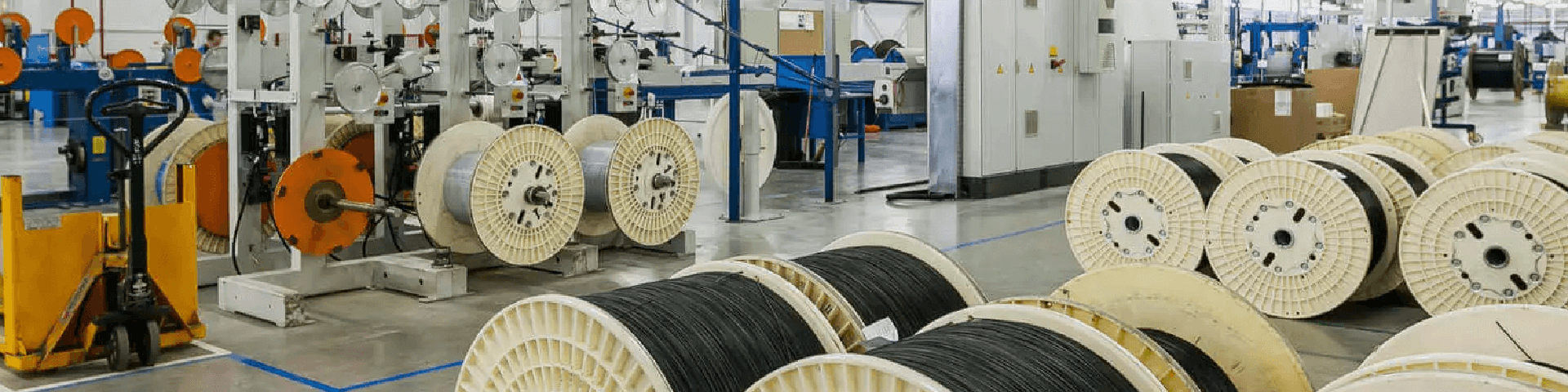

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.