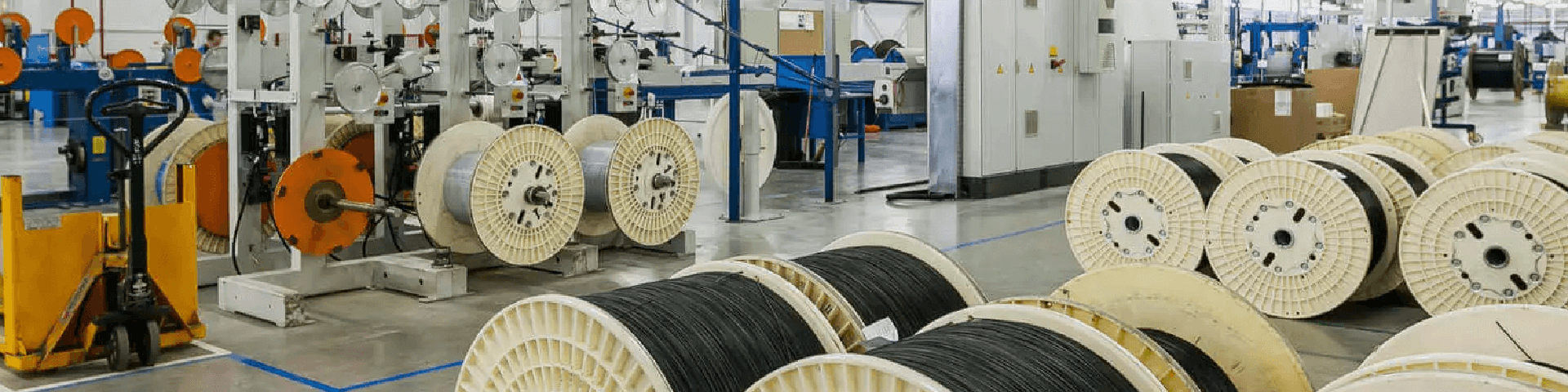

Packing Material:

Non-returnable wooden drum.

Both ends of the fiber optic cables are securely fastened to the drum and sealed with a shrinkable cap to prevent ingress of moisture.

• Each single length of cable shall be reeled on Fumigated Wooden Drum

• Covered by plastic buffer sheet

• Sealed by strong wooden battens

• At least 1 m of inside end of cable will be reserved for testing.

• Drum length: Standard drum length is 3,000m±2%;

Cable printing:

The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

1. Cable type and number of optical fiber

2. Manufacturer name

3. Month and Year of Manufacture

4. Cable length

Drum marking:

Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with the following:

1. Manufacture name and logo

2. Cable length

3. Fiber cable types and number of fibers,etc

4. Rollway

5. Gross and net weight

Port:

Shanghai/Guangzhou/Shenzhen

Lead Time:

| Quantity(KM) |

1-300 |

≥300 |

| Est.Time(Days) |

15 |

To be begotiated! |

Note:The Packing standard and details as above is estimated and final size & weight shall be confirmed before shipment.

Remark: The cables are packed in carton, coiled on Bakelite & steel drum. During transportation, right tools should be used to avoid damaging the package and to handle with ease. Cables should be protected from moisture,kept away from high temperature and fire sparks,protected from over bending and crushing,protected from mechanical stress and damage.

<s