Renewable Design for Direct Buried Fiber Cable - Single Layer Overhead All-Dielectric Self-Supporting 2/4/6/8/12/24 Core ADSS Cable For Mini Span – GL Technology Detail:

Application:

Self-Support Aerial installation,Outdoor;

Features:

1,It can be erected without powering off;

2,AT sheath, excellent electric trackingresistance;

3,Light weight, small cable diameter, reducing the influence of wind and ice, on the tower and support load, large span,the largest span 200 meters;

4,With excellent tensile properties and temperature characteristics, life expectancy is greater than 30 years.

Advantages:

1,Good aramid yarn have excellent tensile performance;

2,Fast delivery,200km ADSS cable regular production time about 10 days;

3,Can using glass yarn instead of aramid,to prevent mouse bite.

Characteristic:

1,Suitable for use on distribution and high voltage transmission lines with mini spans or self supporting installation for telecommunication ;

2,Track -Resistant outer jacket available for the high voltage;

3,Line where space potentials up to 35KV;

4,Gel-Filled buffer tubes are S-Z stranded;

5,Instead of Aramid yarn or glass yarn,there is no support or messenger wire required. Aramid yarn is used as the strength member to assure the tensile and strain performance for mini span (usually below 150 meters);

6,The fiber counts from 2-288 fibers.

OEM Services is available!

E-mail:[email protected]

Product detail pictures:

Related Product Guide:

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Renewable Design for Direct Buried Fiber Cable - Single Layer Overhead All-Dielectric Self-Supporting 2/4/6/8/12/24 Core ADSS Cable For Mini Span – GL Technology, The product will supply to all over the world, such as: Suriname , Switzerland , Benin , Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

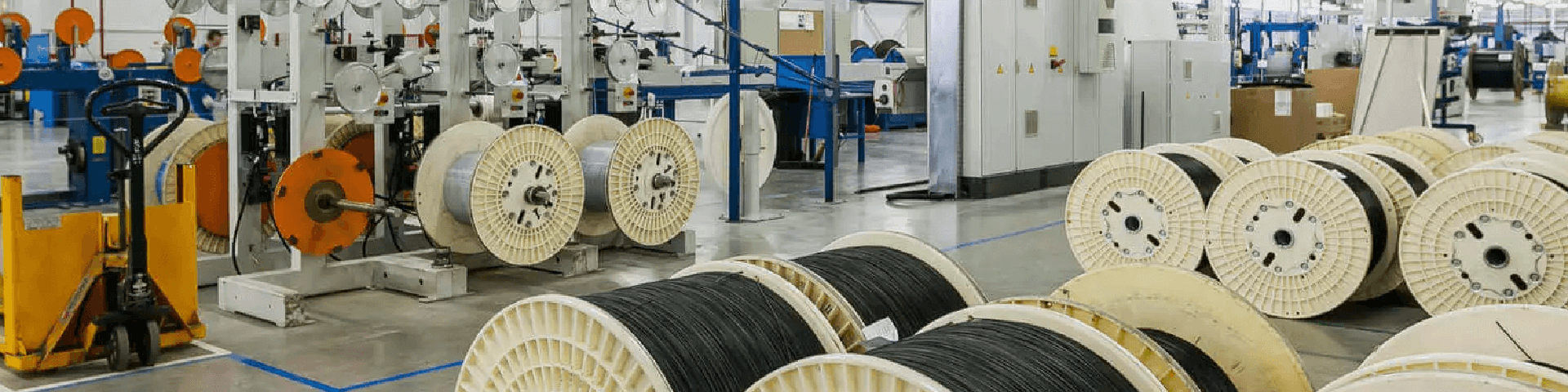

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.