2. Technical Specification

2.1 Optical Characteristics

2.2 Dimensional Characteristic

3. Test Requirements

Approved by various professional optical and communication product institution, GL also conduct various in-house testing in its own Laboratory and Test Center. GL also conduct test with special arrangement with the Chinese Government Ministry of Quality Supervision & Inspection Center of Optical Communication Products (QSICO). GL possess the technology to keep its fiber attenuation loss within Industry Standards.

The cable is in accordance with applicable standard of cable and requirement of customer. The following test items are carried out according to corresponding reference. Routine

4. Packing

4.1Fiber Reel The label that includes the following information shall be attached on each shipping spool:

Fiber Type (G.652D)

Fiber ID Fiber Length

Attenuation at 1310nm & 1550nm

Mode field diameter

Spool box size: 550mm*540mm*285mm, which could take in 8 spools of 25.2KM length fiber or 4 spools of 50.4KM

length fiber. 4.3Test Report Measured fiber test report for each shipment shall be submitted to customer in the form of data sheet and sending the test report using the email at least with the following items.

Fiber ID

Delivery length and actual length

Attenuation at 1310nm &1383nm & 1550nm & 1625nm

Attenuation vs Wavelength

Cable Cutoff Wavelength

Mode Field Diameter at 1310nm

Geometry of fiber cladding and coating

Chromatic Dispersion

PMD at 1550nm

2. Technical Specification

2.1 Optical Characteristics

2.2 Dimensional Characteristic

Approved by various professional optical and communication product institution, GL also conduct various in-house testing in its own Laboratory and Test Center. GL also conduct test with special arrangement with the Chinese Government Ministry of Quality Supervision & Inspection Center of Optical Communication Products (QSICO). GL possess the technology to keep its fiber attenuation loss within Industry Standards.

The cable is in accordance with applicable standard of cable and requirement of customer. The following test items are carried out according to corresponding reference. Routine

4. Packing

4.1Fiber Reel The label that includes the following information shall be attached on each shipping spool:

Fiber Type (G.652D)

Fiber ID Fiber Length

Attenuation at 1310nm & 1550nm

Mode field diameter

Spool box size: 550mm*540mm*285mm, which could take in 8 spools of 25.2KM length fiber or 4 spools of 50.4KM

length fiber. 4.3Test Report Measured fiber test report for each shipment shall be submitted to customer in the form of data sheet and sending the test report using the email at least with the following items.

Fiber ID

Delivery length and actual length

Attenuation at 1310nm &1383nm & 1550nm & 1625nm

Attenuation vs Wavelength

Cable Cutoff Wavelength

Mode Field Diameter at 1310nm

Geometry of fiber cladding and coating

Chromatic Dispersion

PMD at 1550nm

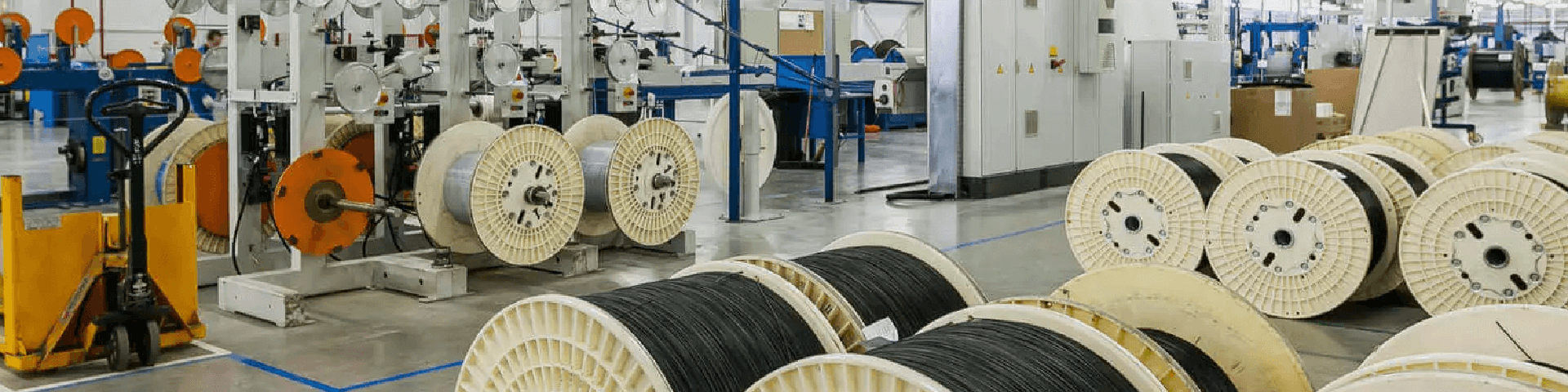

Optical Cable Factory

In 2004, GL FIBER established the factory to produce optical cable products, mainly producing drop cable, outdoor optical cable, etc.

GL Fiber now have 18 sets of coloring equipments, 10 sets of secondary plastic coating equipments, 15 sets of SZ layer twisting equipments, 16 sets of sheathing equipments, 8 sets of FTTH drop cable production equipments, 20 sets of OPGW optical cable equipments, and 1 paralleling equipment And many other production auxiliary equipments. At present, the annual production capacity of optical cables reaches 12 million core-km (average daily production capacity of 45,000 core km and kinds of cables can reach 1,500 km) . Our factories can produce various types of indoor and outdoor optical cables ( such as ADSS, GYFTY, GYTS, GYTA, GYFTC8Y, air-blown micro-cable, etc.). the daily production capacity of common cables can reach 1500KM/day, the daily production capacity of drop cable can reach max. 1200km/day, and the daily production capacity of OPGW can reach 200KM/day.